Gear-Steel

High Strength Steel for Aircraft, Helicopter, and Automotive Gears

AMD Corp. is currently offering the production technologies and US patents of Gear-Steel for sale or licensing.

Weight reduction of high-stressed transmission components such as gears, shafts, etc. plays a crucial role in improving fuel economy of aircraft,

helicopter, and automotive. This can be accomplished, among other things, by utilizing the proposed below high strength Gear-Steel.

Grade1 of Gear-Steel: Carburized Steel

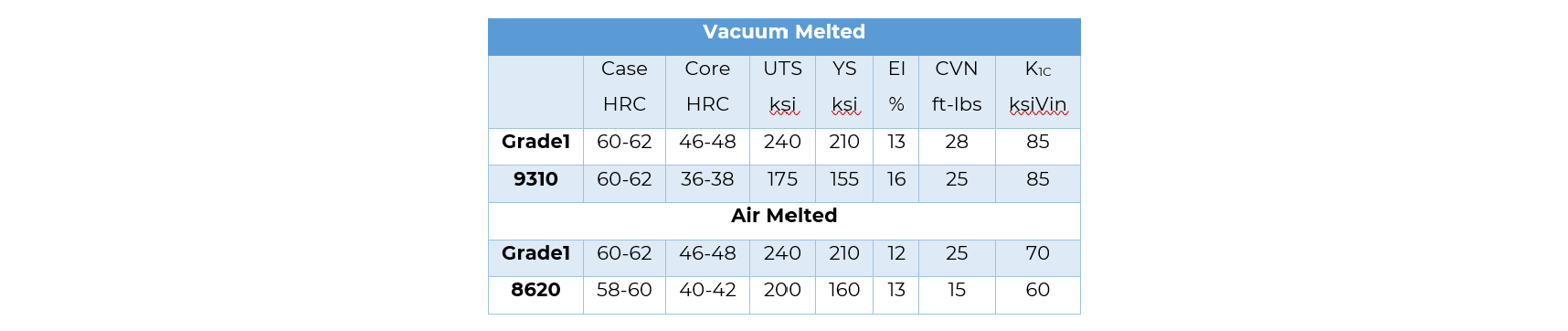

Vacuum melted Grade1 of Gear-Steel possesses higher mechanical properties than the commercial aircraft vacuum melted and carburized 9310 VAC

steel. Carburized Grade1 has a case hardness of HRC 60-62 and a core hardness of HRC 46-48 vs. carburized 9310 VAC of HRC60-62 and of HRC 36-38

respectively while ductility and toughness are almost the same. Higher strength of the core of Grade1 allows for the reduction in weight of gears by

decreasing their cross-section thicknesses. Projected weight reduction is estimated to be ~ 15%, while the cost of raw materials of vacuum melted

Grade1 is 25% lower compared to the cost of 9310 VAC.

Air melted carburized Grade1 is applicable for car and truck gears as well as shafts, axels, other highly stressed components. A comparison of the air melted carburized Grade1 and the commercial carburized SAE 8620 steel shows that Grade1 has a higher case and core hardness at approximately the same ductility and toughness compared to the carburized SAE 8620.

Table1 shows a comparison of ASTM standard mechanical properties of the vacuum melted Grade1 and 9310 VAC steel and the air melted Grade1 and SAE 8620 steel at room temperature (r.t.). The projected weight reduction of the components made from Grade1 is estimated of ~ 15% compared to the same components made from SAE 8620 steel.

Table 1

Wherein: HRC case and core, UTS, YS, El, CVN, and K1C are hardness HRC of case and core, an ultimate tensile strength, yield strength, a total elongation, Charpy v-notch impact toughness energy, and fracture toughness respectively.

Grade2 of Gear-Steel: Deep-Nitriding Steel

Grade2 is a deep nitriding steel perfect for high precision aircraft and helicopter gears. The vacuum melted Grade2 is a high strength substitution of the commercial vacuum melted premium nitriding Nitralloy N VAC steel and it is applicable for the aircraft gears as well as shafts, pinions, and other high-stressed components.

Table 2 shows a comparison of the ASTM standard mechanical properties of the vacuum melted Grade2 and Nitralloy N VAC at r.t. after conventional gas-nitriding.

Table2

The 25% increase in strength of the core of Grade2 allows for the reduction in the weight of the components by reducing the cross-section thickness. The projected weight reduction of the components made from Grade2 is estimated to be ~ 15% compared to the same components made from Nitralloy N VAC.

Grade3 of Gear-Steel: Super-High Strength Steel

Grade3 is a through hardening super-high strength steel for aircraft, helicopter, and automotive gears as well as shafts, axels, other high-stressed components.

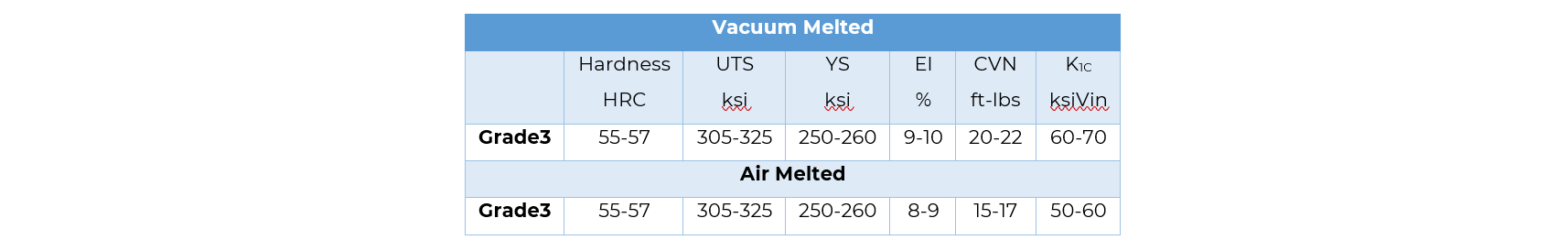

Table3 shows the ASTM standard mechanical properties of the vacuum and air melted Grade3 at r.t. hardened by quenching and tempering.

Table3

The following method of manufacturing of aircraft and helicopter gears made from the vacuum melted Grade3 and automotive gears made from the air melted Grade3 is proposed:

-Normalizing and stress relieving of the hot forged/rolled material

-Rough machining of the gears

-Hardening the gears by quenching and tempering

-Finish machining the gears.

The gears made from the vacuum melted Grade3, substituted with gears made from the vacuum melted 9310 VAR steel allows for a weight reduction of more than 15% without sacrificing the durability and lifetime of the gears.

It should be noted that the strength of Grade3 is more than 10% higher than the strength of 300M steel at approximately the same ductility and toughness.

At the same time, the gears made from the air melted Grade3 allow for a weight reduction of more than 15% without sacrificing their durability and lifetime compared to components made from the air melted SAE 8620 steel.

The production cost of the vacuum and air melted Grade3 is similar to the cost of the vacuum and air melted 300M steel respectively.

Utilizing Grade3 requires additional investment in redesigning gears and upgrading the tools. however, the benefits of utilizing Grade 3 significantly exceed the expenses of its implementation.

*****

AMD Corp. is currently offering the production technologies and US patents of Gear-Steel for sale or licensing

We invite the interested parties to contact us to discuss sale or licensing opportunities